5 Inch gauge railway wagon CHD (part 5)

This section will describe the making of the axle boxes.

Making of the axel boxes.

This picture shows an actual axle box (journal box) on a

wagon similar to the wagon to build.

This picture shows an actual axle box (journal box) on a

wagon similar to the wagon to build.

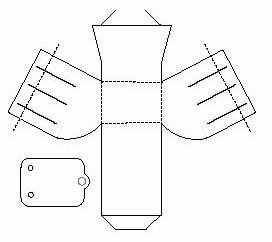

As mentioned in part 2, the actual steel bearing block will be finished

with a dummy axle box. To model the dummy box a paper template was developped first.

As mentioned in part 2, the actual steel bearing block will be finished

with a dummy axle box. To model the dummy box a paper template was developped first.

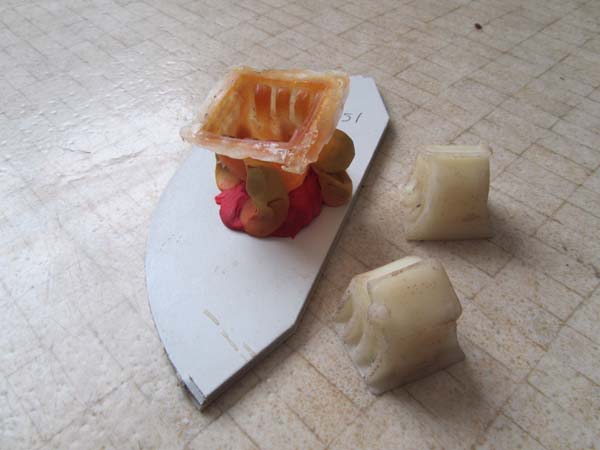

from the paper template a card board model was made which was impregnated with

Epoxy (West System Epoxy) for rigidity.

from the paper template a card board model was made which was impregnated with

Epoxy (West System Epoxy) for rigidity.

The cardboard model was painted with a synthetic paint and lightly greased.

Then a natural liquid rubber was painted over the cardboard mold.

In stead of liquid rubber you can also use a silicon product.

This will form the negative mold.

The grease will enable the mold to be removed from the cardboard model.

The cardboard model was painted with a synthetic paint and lightly greased.

Then a natural liquid rubber was painted over the cardboard mold.

In stead of liquid rubber you can also use a silicon product.

This will form the negative mold.

The grease will enable the mold to be removed from the cardboard model.

Here the epoxy parts coming out of the mold can be seen.

Here the epoxy parts coming out of the mold can be seen.

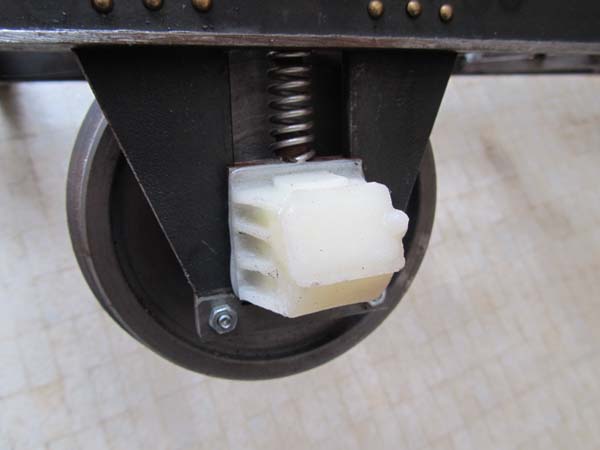

The axle box is glued to the bearing block using epoxy.

The axle box is glued to the bearing block using epoxy.

Back to CHD part 4 of the build. or to the next chapter CHD part 6 of the build.

- www.schaalbouw.nl/projects © 2013 E.Paijmans

-

-

-