Citroën HY welding the tank area

On the right side of the car the petrol tank is located behind the sliding door and before the rear wheel arch. On my car the sill (lower box section) was heavily rusted including parts of the cars jacking point. A repair panel was pop riveted on the rear wheel body panel to strengthen the weakened construction. I started measuring all the (still existing) panels to be able to reproduce repair sections. The advantage of the flat panels and straight edges is that repair panels are relatively easy to make. The omega profiles are more difficult to bend. For this repair I produced them myself from 1mm sheet steel. The box section also had the rail attached for the sliding door.

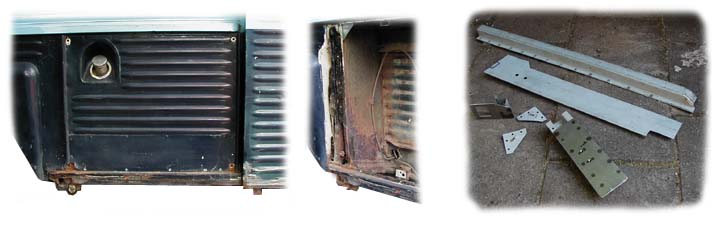

On the first photo you can see the original petrol tank panel with the lower section already replaced and the rust in the area of the jacking point. The second photo is with the petrol tank and pop riveted panel removed. Already the extend of rusted away metal became apparent. The third photo shows the panels produced to repair this section of the car. I removed the petrol pipe from the area where the welding will take place.

The first photo shows the cleaned area with cut out parts ready for welding. The second photo shows the jacking point reinforcement welded in line with the remaining part of the omega profile. The next picture shows the welding of the rear wheel body panel repair section, which was but welded in place with the clamps also discussed in the DS section of this web site. The next picture shows the welding cleaned up with a grinder. The last photo is showing the final stage in the first part of the repair. Al the metal was protected with an etching two pack filling primer.

The second phase was to weld the box section (a closed omega profile) and the door rail (bend 2mm sheet steel) in place. In the corners a small triangular panel with a M7 nut was welded in place to hold the petrol tank body panel. After grinding down the welds and painting the panels with primer the inside of the petrol tank compartment was cleaned and painted with rust stopping paint before remounting the petrol tank. the last photo is of the finished section.

As indicated before it is quite hard (without a semi professional sheet metal folding machine) to make the omega profiles made of 1mm sheet steel. Therefor I contacted a local firm specialized in this type of job, which produced the profiles in 2 meter length sections for around 15 Euro a piece. 2 of these profiles (4 meters total) will probably be enough to replace all the rusted sections on the car. An other alternative to making the profiles is to obtain parts of the bodywork of a scrap HY. As mentioned the profiles are used everywhere in the car. They will not all be rusted. Same applies for the characteristic body panels with the reinforcement ribs which can be used for repair sections also.

- www.schaalbouw.nl/citroen © 2014 E.Paijmans

-

-

-

-

-

-

-

-